BALUNS AND COAXIAL AERIALS

If you are dealing with radiofrequency aerials you might like to experiment with

the configurations proposed. In fig. 1 there is a balun which transforms an unbalanced

line into a balanced feed. You need to connect a variable capacitor, typically a trimmer

capacitor, between two points on the braid of the terminal part of the coaxial cable as

shown in the drawing. The length and the capacitor value are optimized for operation in

the Citizen Band and 50W cable but the set up is not critical at all and should work at

other frequencies as well. The advantage of this balun is that you can provide a perfectly

balanced feed to the aerial thus compensating for any unbalance introduced by the

topography of the ground around the same aerial. Another interesting application for this

balun is to use it as a power splitter: if you measure the output power relative to ground

(i.e. the cold side of the capacitor), you may adjust the power fed to the two terminals

by simply operating on the capacitor. The phase relationship has not been investigated.

Fig. 2 is a more classical approach to the problem: two quarter wavelength sections of the

same coaxial cable give a balanced output with the least of trouble, but it must be

mentioned that it works well only around the designed frequency, it is not a wideband

balun. Length l is

equal to (l/4)xP where l is the operating wavelength and P is the

propagation factor which depends on the type of dielectric material used in the coaxial

cable as shown in the table:

If you are dealing with radiofrequency aerials you might like to experiment with

the configurations proposed. In fig. 1 there is a balun which transforms an unbalanced

line into a balanced feed. You need to connect a variable capacitor, typically a trimmer

capacitor, between two points on the braid of the terminal part of the coaxial cable as

shown in the drawing. The length and the capacitor value are optimized for operation in

the Citizen Band and 50W cable but the set up is not critical at all and should work at

other frequencies as well. The advantage of this balun is that you can provide a perfectly

balanced feed to the aerial thus compensating for any unbalance introduced by the

topography of the ground around the same aerial. Another interesting application for this

balun is to use it as a power splitter: if you measure the output power relative to ground

(i.e. the cold side of the capacitor), you may adjust the power fed to the two terminals

by simply operating on the capacitor. The phase relationship has not been investigated.

Fig. 2 is a more classical approach to the problem: two quarter wavelength sections of the

same coaxial cable give a balanced output with the least of trouble, but it must be

mentioned that it works well only around the designed frequency, it is not a wideband

balun. Length l is

equal to (l/4)xP where l is the operating wavelength and P is the

propagation factor which depends on the type of dielectric material used in the coaxial

cable as shown in the table:

Dielectric |

P |

Typical Cable |

Solid polyethylene |

0.665 |

RG 58 / RG 11 |

Polyethylene/air |

0.835 |

RG 62 / RG 79 |

Fluorocarbon (Teflon) |

0.675 |

RG 94 / RG 209 |

Foam polyethylene |

0.816 |

TV cable |

The balun in fig. 2 can be wired also as in fig. 3. In fact, points A and B are at

the same potential and can be connected together. Nothing changes from the electrical

point of view but it can make a more compact construction in certain circumstances. The

first application will allow you to install a CB car aerial in any other place without the

need of the metal body of the car (fig. 4). The vertical section of the coaxial cable is

short-circuited at the lower end. You might need to adjust the length of the whip, once in

its final place, because distance d is to be subtracted from the total length of

the car aerial.

The balun in fig. 2 can be wired also as in fig. 3. In fact, points A and B are at

the same potential and can be connected together. Nothing changes from the electrical

point of view but it can make a more compact construction in certain circumstances. The

first application will allow you to install a CB car aerial in any other place without the

need of the metal body of the car (fig. 4). The vertical section of the coaxial cable is

short-circuited at the lower end. You might need to adjust the length of the whip, once in

its final place, because distance d is to be subtracted from the total length of

the car aerial.

The typical application is shown in fig. 5. Two different lengths are given: one applies to 50W cables and baluns and the other applies to 75W cables and baluns (fig. 7), these values are good for the design of receiving FM or TV aerials right up to UHF. It must be said that these designs are narrow band aerials and are not suitable to cover a wide frequency range. This means that if you tune to a specific TV channel you will get a performance that could be better than a Yagi but gives poor results at other channels. One way around is to purposefully mismatch the design in order to cover a wider range but I was unable to assess how good this solution was.

If you

find that the aerial is too long at the working frequency, you could apply the design of

fig. 6 where a coil is inserted at the base of the aerial. The coil is made with 17 turns

of 2mm electric wire on a 17mm form. These data are valid for the 27Mhz band and must be

properly scaled at other frequencies. In all cases the vertical coax must be shorted at

the far end because it works also as an impedance matcher for the rest of the aerial.

Installation can be vertical, as shown in the drawings, or horizontal.

If you

find that the aerial is too long at the working frequency, you could apply the design of

fig. 6 where a coil is inserted at the base of the aerial. The coil is made with 17 turns

of 2mm electric wire on a 17mm form. These data are valid for the 27Mhz band and must be

properly scaled at other frequencies. In all cases the vertical coax must be shorted at

the far end because it works also as an impedance matcher for the rest of the aerial.

Installation can be vertical, as shown in the drawings, or horizontal.

All the mentioned aerials were

tested in the 27Mhz band with satisfactory results: best performance being from the design

of fig. 5. Gain was measured between 6 and 9 dB but the instrument available was not very

accurate and I cannot bet on the number reported. As a receiving aerial it was tested in

the FM range, VHF and UHF: in the VHF range I could see a TV channel that I was unable to

see with a 4 element Yagi; in the UHF range the mechanical construction is rather critical

due to the small size and the need of a wideband aerial becomes a major drawback.

All the mentioned aerials were

tested in the 27Mhz band with satisfactory results: best performance being from the design

of fig. 5. Gain was measured between 6 and 9 dB but the instrument available was not very

accurate and I cannot bet on the number reported. As a receiving aerial it was tested in

the FM range, VHF and UHF: in the VHF range I could see a TV channel that I was unable to

see with a 4 element Yagi; in the UHF range the mechanical construction is rather critical

due to the small size and the need of a wideband aerial becomes a major drawback.

SINGLE LED FLASHER

Flashing a LED should not require a complex circuit. A

reverse biased transistor does the job in a nice way. Circuit "a"

flashes the LED twice a second: changing the capacitor and/or the resistor will change the

frequency, also the supply voltage will influence its frequency of operation. A BC337 can

be used instead of the 2N2222A; in this case the supply voltage can be lowered to 9V.

Circuit "b" gives the same result but it will work directly off

the mains, so be careful with the live wire because it can be a hazard if you do not take

all necessary precautions. If the mains voltage is 110VAC the resistor should be decreased

from 100K to 47K. If a BC337 is used, then the resistor is 390K for a 220V mains and 180K

for a 110V mains. The zener is not required for its operation: it is only a safety measure

that avoids voltage build up if the LED gets disconnected. When you reconnect it, the

current surge will destroy the transistor and the LED. The capacitor could be damaged as

well.

Flashing a LED should not require a complex circuit. A

reverse biased transistor does the job in a nice way. Circuit "a"

flashes the LED twice a second: changing the capacitor and/or the resistor will change the

frequency, also the supply voltage will influence its frequency of operation. A BC337 can

be used instead of the 2N2222A; in this case the supply voltage can be lowered to 9V.

Circuit "b" gives the same result but it will work directly off

the mains, so be careful with the live wire because it can be a hazard if you do not take

all necessary precautions. If the mains voltage is 110VAC the resistor should be decreased

from 100K to 47K. If a BC337 is used, then the resistor is 390K for a 220V mains and 180K

for a 110V mains. The zener is not required for its operation: it is only a safety measure

that avoids voltage build up if the LED gets disconnected. When you reconnect it, the

current surge will destroy the transistor and the LED. The capacitor could be damaged as

well.

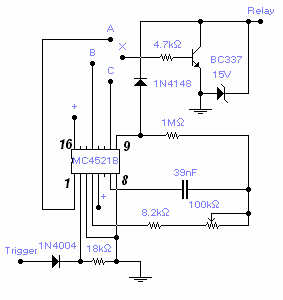

LONG DELAY TIMER

A max. delay of 20 hours is achieved by this relatively simple circuit. A permanent

ground, or no signal, at the trigger input starts the timer. A ground at the relay output

is available after a set time that depends on the connection of the transistor base (X) to

one of the counter output: connection with (C) gives a min. delay of 1m 40s and max. of

18m 30s. Connection with (B) gives a min. delay of 13m 20s and max. of 2h 28m. Connection

with (A) gives a min. delay of 1h 47m and max. of 20h. Supply voltage is between 6 and 15V

and longer delay could be obtained by increasing the capacitor value up to 10 times with a

delay in excess of 1 week. A positive at the trigger input will reset the counter. Adjust

the 100K pot. for the desired timing. The load is typically a relay but any load with a

max. current of 200 mA will work fine. Admittedly this is not a very original circuit but

can save some time if you need to build one.

A max. delay of 20 hours is achieved by this relatively simple circuit. A permanent

ground, or no signal, at the trigger input starts the timer. A ground at the relay output

is available after a set time that depends on the connection of the transistor base (X) to

one of the counter output: connection with (C) gives a min. delay of 1m 40s and max. of

18m 30s. Connection with (B) gives a min. delay of 13m 20s and max. of 2h 28m. Connection

with (A) gives a min. delay of 1h 47m and max. of 20h. Supply voltage is between 6 and 15V

and longer delay could be obtained by increasing the capacitor value up to 10 times with a

delay in excess of 1 week. A positive at the trigger input will reset the counter. Adjust

the 100K pot. for the desired timing. The load is typically a relay but any load with a

max. current of 200 mA will work fine. Admittedly this is not a very original circuit but

can save some time if you need to build one.

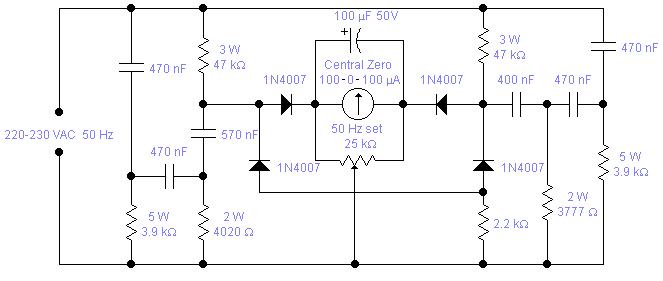

MAINS FREQUENCY METER

Mains

frequency is pretty stable and it is unlikely that you have to measure it but if

you have an emergency generator you might find this circuit useful as it will

give an indication whether the generator is running too fast or too slow.

Actually you can use the mains frequency to calibrate it by adjusting the 25K

multiturn trimmer until it reads 0. The odd looking components values are easily obtained

using standard values: 3777 is 3900 in parallel with 120KW, 4020 is 3900 and

120 in series, 570nF is 470 with 100nF in parallel and 400nF is 4 x 100nF

capacitors in parallel. Components should be chosen for their stability and

precision. 1% tolerance would be ideal but 5% is acceptable so long as you

measure them with a good meter. Capacitors should be properly rated for direct

connection to the mains and resistors should have a low temperature coefficient

as it will adversely affect the zero setting and change the filters response.

The 100mF capacitor could be

occasionally reverse biased with a voltage of 0.1-0.2 V. There is no problem for

the capacitor which is generously rated. Operation is quite

simple: connect it first to the mains, wait about 4-5 minutes until all

resistors reach their working temperature, calibrate, and then connect to the

generator. Variation in the mains voltage will not change

the zero setting but will make the meter more or less sensitive: for

example, a reading of 51 Hz will show as 51.1 with a 10% supply voltage increase.

Mains

frequency is pretty stable and it is unlikely that you have to measure it but if

you have an emergency generator you might find this circuit useful as it will

give an indication whether the generator is running too fast or too slow.

Actually you can use the mains frequency to calibrate it by adjusting the 25K

multiturn trimmer until it reads 0. The odd looking components values are easily obtained

using standard values: 3777 is 3900 in parallel with 120KW, 4020 is 3900 and

120 in series, 570nF is 470 with 100nF in parallel and 400nF is 4 x 100nF

capacitors in parallel. Components should be chosen for their stability and

precision. 1% tolerance would be ideal but 5% is acceptable so long as you

measure them with a good meter. Capacitors should be properly rated for direct

connection to the mains and resistors should have a low temperature coefficient

as it will adversely affect the zero setting and change the filters response.

The 100mF capacitor could be

occasionally reverse biased with a voltage of 0.1-0.2 V. There is no problem for

the capacitor which is generously rated. Operation is quite

simple: connect it first to the mains, wait about 4-5 minutes until all

resistors reach their working temperature, calibrate, and then connect to the

generator. Variation in the mains voltage will not change

the zero setting but will make the meter more or less sensitive: for

example, a reading of 51 Hz will show as 51.1 with a 10% supply voltage increase. Full scale deflection is

around +/- 2 Hz. If you wish to accommodate a wider range of +/- 3.5 Hz, typical

for a petrol driven generator, you have to change the 2.2KW resistor to

12KW.

Full scale deflection is

around +/- 2 Hz. If you wish to accommodate a wider range of +/- 3.5 Hz, typical

for a petrol driven generator, you have to change the 2.2KW resistor to

12KW.

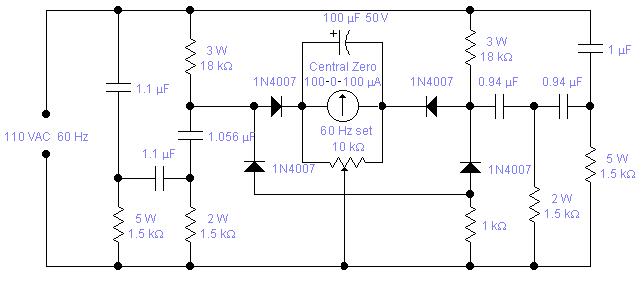

WARNING! This circuit is directly connected to the mains and should be assembled in a box which will avoid access to any of its part and care must be exercised when calibrating the unit. If you live in the States or you have a 110 VAC, 60 Hz mains, you may try the second circuit: the reported values are calculated values, I did not actually test the unit. The odd capacitors values are easily obtained with the combination of standard values: 0.94 is 2 x 0.47 in parallel, 1.056 is 1mF + 56nF in parallel and 1.1 is 1 + 0.1mF.

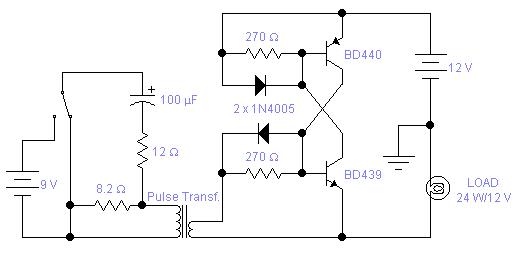

ELECTRONIC RELAY

In

some applications where you require speed of operation and no contact

bouncing, you may find this circuit helpful. The medium power complementary pair

will switch on and off a load up

to 3A. You may modify the

circuit to carry up to 10A using suitable power transistors and diodes. The left

side of the circuit shows a typical drive. This electronic relay will latch in the on or

off position depending on the direction of the pulse going through the primary

winding of the transformer. You may omit the capacitor altogether; in this case

the circuit behaves very much like the coil of a relay: when you apply a voltage

to the primary it will switch on and when you remove the voltage it will switch

off. The drawback in this second case is that there is a large amount of power

dissipated in the 12W resistor which must be rated

accordingly. The pulse transformer is recovered from a faulty electronic neon

light. The drive circuit for these lamps always includes a pulse transformer.

The higher impedance, or resistance, is the primary and the other winding is the

secondary. The measured resistance was below 0.4W and

the inductance was 680 and 47mH for the primary and

secondary respectively. The ideal would be a pulse transformer with two secondary windings so

that both transistors could be driven but you have the same

results if the drive is applied to one transistor only. The circuit has its limitations: there is a voltage drop

across the switch, in the on state, between 0.7 and 1V, this may not be

acceptable in low voltage applications; it will work only with DC supplies and

there is a minimum sustain current, 12mA in the circuit shown. Below this

current the switch will revert to its off state. You may, of course, design a

circuit with low power transistors with a sustain current of only a few mA

if necessary.

In

some applications where you require speed of operation and no contact

bouncing, you may find this circuit helpful. The medium power complementary pair

will switch on and off a load up

to 3A. You may modify the

circuit to carry up to 10A using suitable power transistors and diodes. The left

side of the circuit shows a typical drive. This electronic relay will latch in the on or

off position depending on the direction of the pulse going through the primary

winding of the transformer. You may omit the capacitor altogether; in this case

the circuit behaves very much like the coil of a relay: when you apply a voltage

to the primary it will switch on and when you remove the voltage it will switch

off. The drawback in this second case is that there is a large amount of power

dissipated in the 12W resistor which must be rated

accordingly. The pulse transformer is recovered from a faulty electronic neon

light. The drive circuit for these lamps always includes a pulse transformer.

The higher impedance, or resistance, is the primary and the other winding is the

secondary. The measured resistance was below 0.4W and

the inductance was 680 and 47mH for the primary and

secondary respectively. The ideal would be a pulse transformer with two secondary windings so

that both transistors could be driven but you have the same

results if the drive is applied to one transistor only. The circuit has its limitations: there is a voltage drop

across the switch, in the on state, between 0.7 and 1V, this may not be

acceptable in low voltage applications; it will work only with DC supplies and

there is a minimum sustain current, 12mA in the circuit shown. Below this

current the switch will revert to its off state. You may, of course, design a

circuit with low power transistors with a sustain current of only a few mA

if necessary.

In

order to generate a single note you may try these simple circuits. With only

three components you may implement some basic buzzers. You need a telephone

earpiece for the first circuit. Any old telephone set has got one of those

magnetic earpiece that is right for our purposes. Add an extra capacitor and a

transistor and you have your buzzer. Frequency of operation is about 1800 Hz and

the capacitor must be changed if you wish to have a different frequency. The

second circuit is implemented with a ceramic sounder: its intrinsic capacity is

used to make another simple buzzer. Working frequency is 800 Hz and power drain

is really low. The operating voltage is 9,5 - 20V for the circuit with the

ceramic sounder and 8 - 16V for the other circuit. Do not expect a loud sound

level: it is rather limited just as the current drain is. These buzzers are

suitable for audio signaling on portable devices and wherever it is necessary to

have a sound source implemented with a minimum components count. Not all

transistors will oscillate: you have to use the specified type although I found

that the BC109 and 2N2222A will also work albeit at a slightly different

voltage.

In

order to generate a single note you may try these simple circuits. With only

three components you may implement some basic buzzers. You need a telephone

earpiece for the first circuit. Any old telephone set has got one of those

magnetic earpiece that is right for our purposes. Add an extra capacitor and a

transistor and you have your buzzer. Frequency of operation is about 1800 Hz and

the capacitor must be changed if you wish to have a different frequency. The

second circuit is implemented with a ceramic sounder: its intrinsic capacity is

used to make another simple buzzer. Working frequency is 800 Hz and power drain

is really low. The operating voltage is 9,5 - 20V for the circuit with the

ceramic sounder and 8 - 16V for the other circuit. Do not expect a loud sound

level: it is rather limited just as the current drain is. These buzzers are

suitable for audio signaling on portable devices and wherever it is necessary to

have a sound source implemented with a minimum components count. Not all

transistors will oscillate: you have to use the specified type although I found

that the BC109 and 2N2222A will also work albeit at a slightly different

voltage.

![]() Eager

for more

Eager

for more

Full astern to main

page

Full astern to main

page

![]()