COINSHOOTER Metal Detector

The Coinshooter employees a sophisticated, VLF induction-balance detection

system that responds only to the proximity of nonferrous metallic objects,

it ignores items containing iron. Moreover, the project can be adjusted

to compensate for the soil’s mineral

content, thus minimizing false indications. The Coinshooter can detect

a dime in an air test at four inches or a half-dollar at eight inches.

Depth of detection in the field will depend on ground conditions, but detection

depth will always be less than air test. Unlike detectors that employ

conventional beat-frequency oscillator circuits, the Coinshooter does not

require the user to monitor the pitch of a continuous tone. Rather, it

alerts the user to the proximity of nonferrous metal by generating one

or more beeps. Also, it is lightweight (about 2 lb.) and well balanced.

Total construction cost is approximately

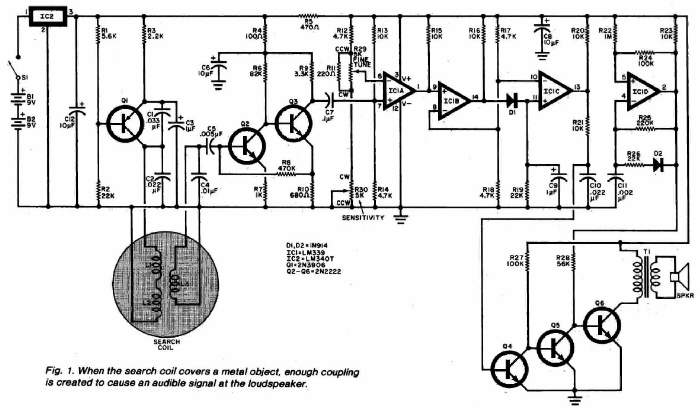

$35, and less if salvaged parts are used. About the Circuit. The Coinshooter

appears schematically in Figure 1. Coplanar search coils are formed by

placing a receiving coil (L3) over a folded-loop transmitting coil (L1

and L2) so that there is little if any coupling between them unless there

is metal present in the search field. A Colpitts oscillator comprising

Q1 and its associated passive components generates a 6.2-kHz signal that

drives the transmitting coil. Transistors Q2 and Q3 amplify the low-level

signal induced across receiving coil L3 when no metal objects are present

in the search field so that a 1-volt pp

signal appears at the collector of Q3. Capacitor C7 couples this signal

to the non-inverting input of voltage comparator IC1A. The input circuit

of the comparator rectifies the ac signal, resulting in the generation

of a slightly negative voltage that subtracts from the

positive bias voltage supplied by divider R13-R14. Potentiometers R29 and

R30 determine the magnitude of the reference voltage applied to the inverting

input of ICIA and hence the detector circuit’s sensitivity. They are adjusted

so that the voltages at the two inputs are practically equal. When the

voltage at the non-inverting input of the comparator becomes more positive

than that at the inverting input, the output terminal (pin 1) switches

to the positive supply voltage. This positive pulse toggles comparators

IC1B and IC1C, which are connected in.cascade and whose inverting inputs

are biased to one-half the positive

supply voltage. The charging of C9 via D1 and the discharging of C9 through

R19 stretches the pulse. Transistor Q4 is triggered into conduction by

the elongated pulse that appears at the output of IC1C, cutting off Q5.

When Q5 is cut off, Q6 amplifies the tone produced by the audio oscillator

comprising IC1D and its associated passive components. The current flowing

through the primary of audio-output transformer T1 and transistor Q6 increases

the voltage drop across R5, and this upsets the bias applied to the inverting

input of IC1A. As a result, the outputs of IC1A, IC1B, and IC1C go low,

transistor Q4 cuts off, and transistor Q5 saturates, shunting the base

drive of Q6 to ground and cutting that transistor off. This silences the

loudspeaker and allows C8 to charge again to the full positive supply voltage.

The higher voltage across the capacitor allows IC1A to change state again

if the nonferrous metal object is still within the search field. Iron objects

or mineralized ground within the search field will produce an increase

in the amplitude of the signal at the collector of Q3 and thus a less positive

bias at the non-inverting input of IC1A. In contrast, the presence of coins

or other. nonferrous metal objects within the search field will cause a

smaller signal to appear at the collector of Q3 and a more positive bias

at the non-inverting input of the first voltage comparator. This allows

the Coinshooter to locate coins and other items of interest while ignoring

nails, bottle caps, and other junk pieces of iron and steel. When

a small nonferrous item quickly enters and exits the search field, the

loudspeaker will generate a single beep. If the object enters and

remains in the search field, a series of beeps will be produced. Its rate

of repetition will vary with the settings of potentiometers R29 and R30,

the size of the object, and the distance between the object and the search

coil. The pitch of the beep is determined by the values of C11 and the

resistances in the feedback loop, as

well as by the supply voltage. Its frequency is nominally 1.3 kHz.

B1,B2 9v alkaline battery

C1 0.033 mF, 50v Mylar capacitor

C2, C10 0.022 mF, 50v Mylar capacitor

C3, C9 1 mF, 16v tantalum capacitor

C4 0.01 mF, 50v ceramic disc capacitor

C5 0.005 mF, 50v ceramic disc capacitor

C6, C8, C12 10 mF, 18v aluminum electrolytic capacitor

C7 0.1 mF, 50v Mylar capacitor

C11 0.002 mF, 50v ceramic disc capacitor

D1, D2 1N914 silicon switching diode

IC1 LM339 quad voltage comparator

IC2 LM340T-8 +8v regulator

L1, L2 Air-core inductor: 175 turns of No. 30

wire wound 9-1/2 inches in diameter (see

text)

L3 Air-core inductor: 550 turns of No. 38

enamelled wire on 3-1/2" diam.

Q1 2N3906 or similar pnp silicon switching

transistor

Q2 through Q6 2N2222 or similar npn silicon switching

transistor

The following, unless otherwise specified, are 1/4 watt, 5%-tolerance,

carbon composition fixed resistors.

R1 5.6 kW

R2, R19, R26 22 kW

R3 2.2 kW

R4 100W

R5 470W

R6 82 kW

R7 1 kW

R8 470 kW

R9 3.3 kW

R10 680W

R11 220W

R12, R14, R17, R18 4.7 kW

R13, R15, R16, R20, R21, R23 10 kW

R22 1 MW

R24, R27 100 kW

R25 220 kW

R28 56 kW

R29 5 kW, linear-taper potentiometer

R30 5 kW, linear-taper potentiometer with

shaft-actuated SPST switch

S1 SPST switch (part of R30)

SPKR 2-1/4 inch, 8W dynamic speaker

T1 1kW:8W miniature audio output transformer

Misc. - Suitable enclosure, perforated or printed-circuit board, single-conductor

shielded cable, hookup wire, No. 30 and No. 38 enamelled copper magnet

wire, battery clips, battery holders, circuitboard standoffs, grommets

or other suitable strain reliefs for shielded cable, PVC electrical tape

or silicone cement or other suitable insulating material, 12 -inch-by-

12-inch sheet of 1/4-inch plywood, monofilament fishing line, 3/4-inch

masking tape, epoxy, hot-melt, and PVC glues, 4 feet of 1/2-inch O.D.,

schedule 125 PVC pipe, 2 feet of 1/2-inch, schedule 40 PVC pipe, 90°

elbow PVC pipe joint, 135° elbow PVC pipe joint, tee PVC pipe joint,

PVC pipe cap, bicycle steering-bar handgrip, lead buckshot, resin sealant,

white paint, solder, hardware, aluminum foil etc.

Power for the Coinshooter circuit is supplied by two series-connected

nine-volt batteries. An IC voltage regulator provides a constant supply

potential to the rest of the circuit until the batteries are nearly exhausted.

Quiescent current demand is approximately 10 mA, so battery replacement

should be infrequent if alkaline cells are used. If desired, the Coinshooter

can be powered by a single nine-volt battery and the regulator IC omitted.

However, the circuit is sensitive to changes in supply voltage, and this

alternative is not recommended. But, if this approach is taken, an alkaline

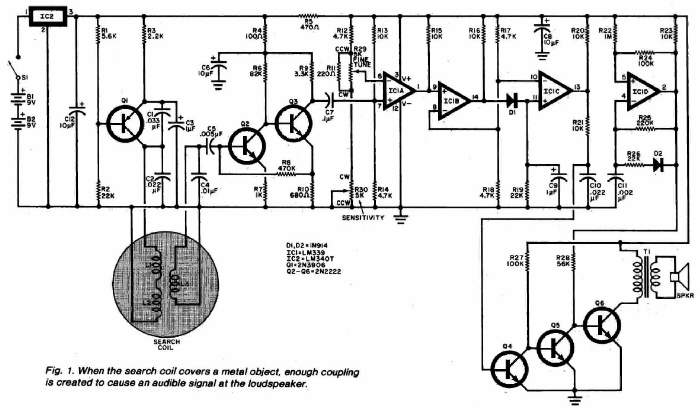

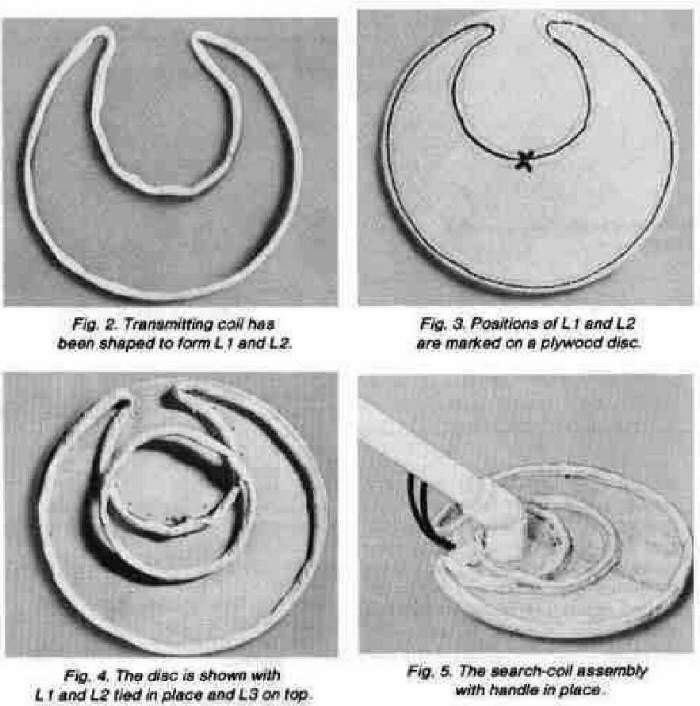

battery must be used. Construction. Procure a circular form 9-1/2"

in diameter on which you can wind the transmitting coil. In assembling

the prototype, a hamper lid was used, but a mixing bowl or cardboard cylinder

would be suitable. Wind a layer of masking tape 3/4-inch wide around the

form so that the adhesive side is exposed. The tape will hold the wire

and make winding the coil much easier. Wind a total of 175 turns of No.

30 enamelled copper wire around then form, keeping the wire as close to

the center of the tape as possible. The last turn should exit the coil

at a point on the circumference 10 inches before the starting point is

reached. Fold the tape around the coil and remove it from the form. Spiral-wrap

the coil tightly with masking tape. Then shape the coil assembly as shown

in Fig. 2 to form the

transmitting coil. (L1 is the large-diameter portion and L2 is the small-diameter

section.) The coils must be shielded so spiral wrap them (starting with

L1 opposite the lead wires) with 1" wide strips of aluminum foil.

Cover the coils completely except for a 1/4" gap between start and

finish of the foil layer. Strip a 6" piece of hookup wire and lay

it

on the foil so that 2" exits next to one of the lead wires. Then spiral

wrap the coils tightly with masking tape, covering the foil completely.

Slip the free ends of the shielded cables exiting the circuit-board

enclosure through the 1/4-inch holes that are bracketed by the smaller

holes and pass the cables through the pipe until they protrude from the

far end. Run a bead of hot-melt or epoxy glue on the pipe and attach the

bottom of the project enclosure to the pipe. Added mechanical support can

be introduced by driving self-tapping screws through the two small holes

in the bottom of the enclosure and into the matching holes that were drilled

into the pipe section.

Feed the free ends of the shielded cables through the two holes at the

other end of the pipe. Insert that end of the pipe into the elbow joint

attached to the plywood disc so that the circuit enclosure faces away from

the coil assembly. Then glue the pipe to the elbow joint using PVC cement,

maintaining the orientation of the enclosure with respect to the coil assembly.

(Note that PVC cement sets quickly.) Solder the conductors of the color-coded

cable to the transmitting coil and the conductors of the other cable to

the receiving coil. The polarities of these connections are unimportant.

Connect the coil shield leads to the outer cable conductors. Insulate the

solder joints using PVC electrical tape, silicone cement, or some other

suitable material. Then cement the cables to the plywood disc in the area

between L3 and the gap in L1 using hot-melt or epoxy glue. Cut 6- and 9-inch

lengths of 1/2-inch O.D., schedule 40 PVC pipe. Assemble a handle using

the lengths of pipe, a

90° elbow PVC pipe joint, a tee PVC pipe joint, a bicycle steering-bar

handgrip and PVC cement. The handgrip is glued to the 9-inch section of

pipe, and one of the two collinear openings of the tee should be glued

to the 39-inch pipe section to which the circuit-board enclosure and the

search coil assembly are attached. PVC cement is fast-setting, so work

quickly and orient the handle such that it is directly above the circuitboard

enclosure. The remaining end of the tee will be left open until the detector

is balanced. Apply power to the circuit and reconnect the oscilloscope

probe between the collector of Q3 and circuit ground.

Suspend the search coil in the air away from any metal and rotate the shaft

of R29 to its minimum-sensitivity setting. Monitor the scope trace

and, if necessary, slightly adjust the position of L3 so that a 1-volt

p-p signal appears at the collector of Q3. Pass a pair of pliers approximately

three inches under the search-coil assembly while monitoring the scope

trace. If the signal level decreases, shift L3 through the null point and

repeat the test. The signal must increase in amplitude when the pliers

are brought near the search-coil assembly, or the detector will ignore

coins and respond to the proximity of ferrous objects. Receiving coil L3

should be positioned as close to the null point as possible yet still provide

an increase in signal amplitude when iron or steel is brought near the

search-coil assembly. Next, pass a dime about three inches under

the search coil and note the slight increase in signal level as displayed

on the oscilloscope. Carefully fix the positions of the coils by bonding

them to the plywood disc with quick-setting epoxy cement. When the epoxy

has cured, remove the scope probe and button up the circuit-board enclosure.

Advance the setting of the SENSITIVITY control until the speaker begins

to beep. Then adjust the FINE TUNE control to silence the speaker. Pass

a pair of pliers three inches below the search coil and note that the speaker

remains silent. Then pass a dime three inches under the coil and note that

the speaker starts to beep. The most sensitive area of the search coil

is near its center.

The search-coil assembly can be coated with two thin applications of resin

to seal it, and then it can be painted white so that it matches the PVC

pipe. The coils must be bonded securely to the disc before the application

of sealant and paint. To minimize the possibility of displacing the coils,

use spray-on resin and paint. If the coils have shifted position before

the resin has cured, a compensating piece of iron or steel can be added

to the

search-coil assembly. Determine whether this has in fact happened by removing

the top of the circuit-board enclosure and reconnecting the oscilloscope

probe between the collector of Q3 and circuit ground. Pass a ferrous object

three inches below the search coil and monitor the scope trace. If the

proximity or iron or steel causes a decrease in signal level, position

a small steel washer on or near receiving coil L3 to correct for the misalignment.

Locate the required position by repeating the test for iron sensitivity

and shifting the location of the washer until the correct response is obtained.

Then fix the washer in place with epoxy cement. Final Assembly and

Use. Grasp the Coinshooter by its handgrip and check it for proper balance.

The search-coil assembly should be parallel with and approximately 2 inches

above the floor. Cut a 3-inch piece of 1/2-inch O.D. schedule 125 PVC pipe,

and glue one end of it to a PVC pipe cap. Fill the pipe section with lead

buckshot and tape its open end closed with PVC electrical tape. Then tape

the shot-laden pipe section to the open end of the tee PVC pipe joint and

recheck the balance of the project.

If it is unbalanced, untape the shot-laden pipe section, remove a little

shot, tape the section closed again and reattach it to the tee PVC pipe

joint. Recheck the balance of the Coinshooter. If necessary, repeat this

procedure until the Coinshooter is properly balanced and feels comfortable

to the hand. When the correct amount of shot has been

determined, remove the pipe section from the tee PVC pipe joint, seal the

shot in the pipe section with epoxy, and cement the section to the tee

after the epoxy has cured. This completes assembly. Take the finished

project outdoors and hold the search coil 4 to 6 inches above the ground.

Apply power to the project and adjust its controls so that the speaker

emits a slow series of beeps. Lower the search coil until it is approximately

2 inches above the ground. The beeping should stop. This occurs because

most soil is mineralized

and affects the Coinshooter much like ferrous objects do. The detector

is now at maximum sensitivity and will detect coins at depths of from 1

to 3 inches, depending on their sizes and positions. Ferrous objects will

not trigger the circuit unless they are very large or very close to the

search coil or both. The Coinshooter will detect aluminum cans, caps and

pull tabs, but it responds best to coins. Raise the search coil from time

to time to check for the slow beeps that indicate maximum detector sensitivity.

Although the circuit is very stable, the FINE TUNE control might have to

be adjusted occasionally to compensate for changes in

ground mineralization, temperature, and, if an unregulated power supply

is used, battery voltage. Always hold the Coinshooter so that the

search-coil assembly is 1 to 2 inches above and parallel to the ground.

Try to keep the search coil at a constant height above the ground. Swing

the loop back and forth in front of you, making overlapping arcs. It is

best to search slowly, but a coin will usually be detected even if the

search coil passes over it

quickly. For best results, operate the circuit as close to its switching

threshold as possible.

When an object has been detected, move the search-coil assembly over it

from front to back and from side to side to pinpoint its location. Keep

in mind that the center of the assembly is its most sensitive point.