|  |

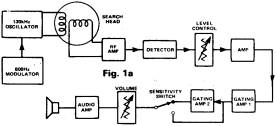

| Fig 1. (MK 1) | F 2. (MK2) |

try but to our surprise we were unable to make any real improvement on the first circuit

using the general principles. We could have reduced the package count by using

an LM389 (which in~cludes three independent transistors plus an audio output

amplifier) but that would have cost more with no real change.

In the original design the transmitter was modulated and the peaks of

the detected signal were gated and enormously amplified (See How It Works and

Fig la). Although we refer to the signal being modulated, it was actually

switched on and off and this resulted in ringing in the tuned circuit.

After literally three weeks solid experimenting we decided to take

another approach. We decided to dispense with a modulated transmitter and work

with DC until the final stages. In the original design the audio frequency was

fixed, being dependent upon the modulator and metal was sensed by an increase

in audio level. However, our ears are highly insensitive to changes in level

but they are however, very sensitive to a change in audio frequency. Once we

had decided to tackle it from this side everything fell into place. For a long

while our voltage controlled oscillator was a unijunction transistor and

although we achieved excellent results we were not satisfied with the unit in

practice and eventually adopted the circuit shown in Fig.3.

FIp. la

(above) shows

the block diagram of the Mark 1. In thus the peaks of

the modulated signal wore gated and enormously amplified. Diagram below shows

the new arrangement. the RF signal, which is unmodulated, is converted to a DC

signal which delves a voltage controlled oscillator (VCO).

IRMk2

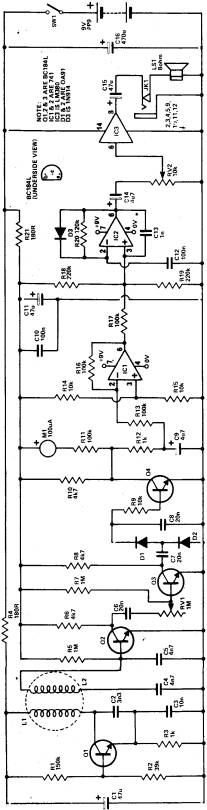

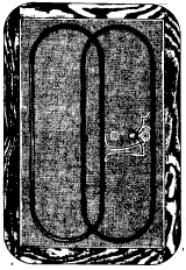

The Coil

We cannot emphasise

enough that the search head is the key to the whole operation: be prepared to

spend some time on this, our own workshop is full of discarded experiments.

The housing

of the coils is not important. In the Mkl we adopted a circular head but this

is difficult for the non-woodworkers to tackle so we went for a rectangular

shape. The coils Li and L2 should be sandwitched between two pieces of

hardboard or plywood separated by thin battens

about 6mm

thick. The top should be built first and the battens fitted

for a

better appearance you can then file off the corners slightly.

To wind the

coils you’ll need to get hold of a cylinder about 140mm (5’Ain) in diameter.

Using 32 swg enamelled copper wire, trap one end onto the former with a piece

of tape and carefully wind 40 turns as close together as possible. Carefully

remove the coil and then wrap tape around it at intervals to keep it from

spreading.

Two

identical coils are required.

Lay one of

the coils into the dish formed from the top of search head and the battens as

you see in the photograph and spot glue it into place except on the part near

the middle. Lay the other coil next, again spot gluing it except near the

middle.

A hole

should be made in this piece of wood to feed through the connecting cable to

the main circuit. This cable must be a four-wire type with individual screening

the

screens are not used at the search coil end but don’t cut them too far back: we

still have a few experiments to try out on our prototype and access to this

screening may be used.

The

Control Box

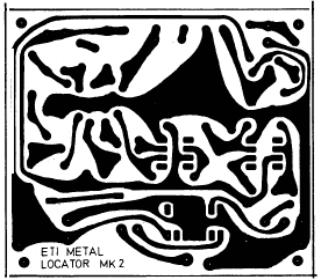

The circuit

should be built up next. Everything except for the controls, the speaker and

the meter are on a single POB. Building this up should present few problems.

Spacing is designed for

eighth watt

resistors and tantalums are used, again to save space though the control box

has plenty of room in

terminal pins to the points shown in the PCB overlay as this will make

connections far easier to make later on.

Assuming

you haven’t got the coil in exactly the right position by luck in the original

setting, you should get an audio tone of about 700Hz from the speaker and the

meter

connected) will be hard over.

If you

don’t get this, adjust RV 1 and it should appear: Back off RV1 until the

frequency falls and then increase it a bit so that the tone is slightly higher

than the minimum.

Now gently

and slowly bend the coils and adjust the overlap till the tone falls. Add a

fewmore blobs of glue but leave yourself with some adjustment. Readjust RV1

again and repeat. Continue to do this until you can no longer get any lower

adjustment on RV1.

Now check

that no metal

is

in the vicinity (don’t forget cuff-links, watches and

rings) and continue the manipulation.

If you use

a scope, monitor the level of the signal of the collector of Q2: when you are

near to a minimum

the level should fall considerably. If all works as

described, bringing

a piece of

metal near the coil should result in the frequency rising. If the frequency

falls instead of rising, continue adjusting. Near the minimum you can reach a

point where the metal firstly adds to the cancellation.

Don’t glue

down the final tiny, tiny adjustments until you are quite certain that all is

OK. The amount of final adjustment is extremely critical as you’ll find out.

General construction

The general

design can be seen from the photographs. We used a Verobox to house the main

circuit and cut a piece of broom-handle at an angle and fitted a bicycle

hand-grip to this. The stem is made up from Marley 22mm cold water plastic

tubing, available from many plumbers. The connection to the search-head was

accomplished by softening a short length of the stem plastic in hot water and

quickly clamping this in a vice. The connectors on the stem are

also Marley

fittings.

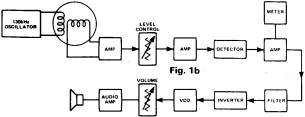

The heart of the circuit is the search coil, L1 and L2, These two coils,

which are essentially identical, are arranged in the same plane with a small

overlap in such a way that there is is practically no inductive coupling

between the two.

There is a minimum

pickup when the fields generated in L1 are cancelled in L2 when in free

air.

Any metal brought into the

magnetic field of L1 will distort the field, causing pickup in L2.

Q1 is a straightforward Colpitt’s oscillator working at a nominal 130

kHz. This type of circuit is very stable and the use of polystyrene capacitors

also help with stability.

The supply to

this stage is separately decoupled by R4 and C1.

The pickup coil L2 is tuned by means of C4 and C5 and amplified by Q2

which feeds th the level control RV1.

This controls the ‘free air’ state of the circuit and is set to the

point where the later stages are just operating.

The signal is further amplified by Q3 (here it is still an RF

signal) and is detected by D1 and D2.

When no metal is in the vicinity of the search coil and with RV1

correctly adjusted, a DC voltage of about 500 mV appears across C8.

R9 increase the effective input impedance of

Q4 as seen by the detector stage.

Q4 is just held off by the voltage available but as soon as metal

distorts the electromagnetic field, L2 produces a large RF signal, a higher

voltage across C8 and a consequent fall (from 8V) in the voltage at the

collector of Q4.

This voltage is also

monitored by the meter in parallel with the load resistor of Q4.

The fall in voltage is dependent upon the

proximity and/or size of metal near the search coil.

It is necessary to ensure that the DC voltage fed to the next stage is

clean and R12 and C9 act as a a filter to remove any residual AC even if this

is at low frequencies.

IC2 (the next but one stage) is a voltage controlled oscillator – but to

operate this so that metal is indicated by a rising note, rather than a falling

one, the voltage at the junction of C9 and R12 has to be inverted and this is

achieved by IC1: in ‘no metal’ conditions there is about 2 V at the output of

this op-amp which rises when metal is near.

This stage quickly saturates to give about 7 V at pin 6.

IC1 has unity gain.

IC2 is a voltage controlled oscillator in ‘no metal’ conditions it gives

about 70 Hz which rise to 500 Hz when metal is present.

Diode D3 gives a rapid recharge to C12 and

affects the mark/space ratio of the output which results in lower battery

consumption.

R20 and C12 can be altered

to give a different range of frequencies if desired.

The output is taken to the volume control and fed to the LM380 audio

power amplifier which in turn feeds the speaker.

The levels of signal around Q2,3,4 are all dependent upon transistor

gain, temperature and supply voltage but this doesn’t matter because the level

control RV1 is adjusted until Q4 just begins to conduct.

Current drain for the complete circuit is in the order of 50 mA.

| Resistors (all at 1/8W 5%) | |

| R1 150k | C13 1n polyester |

| R2 39k | C15 47u 16V electrolytic |

| R3,12 1k | C16 470u 16V electrolytic |

| R4,21 180R | |

| R5,7 1M | semiconductors |

| R6,8,10 4k7 | Q1,2,3,4 BC 184L or equivalent |

| R9,14,15 10k | IC1,2 741 8-pin DIL |

| R11,13,16,17 100k | IC3 LM380 |

| R18,19 220k | D1,D2 OA91 |

| R20 120k | D3 1N914 |

| RV1 1M linear (level) | |

| RV2 10k log (volume) | Miscelaneous |

| Capacitors | LS1 8 ohm minature loudspeaker |

| C1,11 47u 16V tantalum | JK1 stereo jack socket |

| C2 3n3 polystyrene, 5% | M1 100uA level meter |

| L1,L2 see text | |

| C3 10n polystyrene, 5% | PCB - see drawing |

| C4,C5 20n polystyrene | 4-core individually screened cable |

| C9,14 4u7 16V tantalum | Battery and Clip pp9 |

| C10,12 100n polyester | Bicycle hand grip |

| Verobox, 4 1/4 x 7 1/2 x2 1/4 |

Re printed from ETI TOP PROJECTS NO7 (1979)