Return to Home Page

Electric Field Mill Fabrication

by Jim Campbell

jc@izzy.net

Updated April 14, 2001

This page describes the construction of an electric

field mill. This is a device to measure the electric

field strength on earth due to the static electric

field and the charge of clouds passing overhead. It

can also be used to investigate static electricity effects.

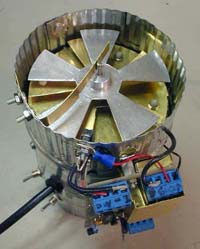

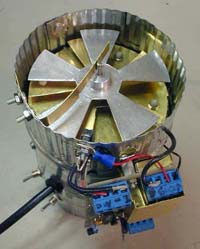

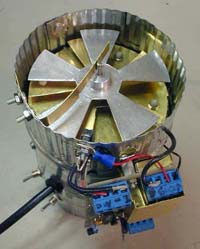

The body and chopper of the field mill are fabricated from a

4 inch diameter duct fan. The signal conditioning electronics

uses a chopper blade position detector and a synchronous detector

to reduce noise and recover the field sign (positive or negative) as

well as magnitude (strength in V/m).

Photographs:

1. Top View

2. Sense Plate Detail

3. Sense Plate Bracket

4. Sense Plate Bracket Detail With Spacer

5. Position Detector Mounting Detail

6. Bottom View

7. Side View

8. Board Backside, Shield Cover Off

9. Board Topside, Shield Cover Off

10. Fan Blades, Before Modification

Figures:

1. Circuit Schematic

2. Plot of Clock and Signal Phase

Web References:

1. Scientific American Amateur Scientist Field Mill Project

2. Scientific American Amateur Scientist Field Mill Project Discussion

3. Lightning Detectors

4. NASA/Marshall Space Flight Center Airborne Electric Field Mill

5. GP-1 Lightning Locator

6. University of Florida Lightning Research Group

7. Experimental E-Field Data

8. Global Atmospherics, Inc.

9. Atmospheric Electricity

HomePage

10. The Earth's Electrical Environment - E.P. Kreider 1986

11. Development of a Lightning Warning System -- Adam Milner

12. Near-real time lightning tracking:

Global Atmospherics, Inc.

13. Intellicast Lighting

14. Lightning strike triggered by a flying airplane

Print References:

1. Martin A. Uman - Lightning, McGraw-Hill Book Company, New

York (1969), 264 pages. Russian translation (1972), revised edition, Dover,

New York (1984). (Available at Borders)

Theory of Operation

The strength of the electric field could be measured, in principle,

by placing a volt meter across plates placed some distance

apart. However, because the meter will have some input

impedance (10 Meg typically), any voltage induced on

the plates will quickly drain away, and would not be

useful for measuring the static field. To make measurements

of the static field, the chopper technique is used. The chopper

blade is arranged over the Sense Plate and rotated so that it

periodically shields, and exposes the Sense Plate to the electric

field. To properly do this, the Rotor must be grounded. The Sense

Plate is grounded through a transconductance amplifier, which

converts the Sense Plate's ground current to a voltage. As the

Sense Plate is exposed to the Field, the field induces ground

currents as it attracts or repels charge from the Sense Plate.

As the plate is shielded from the field, the induced charge drains

away. So the chopper induces an AC ground current which is

proportional to electric field strength.

This AC signal could then be rectified to drive a DC volt

meter or be plotted on a scope. However, by doing this only

the magnitude of the field, not the sign (positive of negative)

would be measured. Also, any noise in the signal would also affect

the output. The signal conditioning for this Field Mill uses a

synchronous demodulation technique to preserve field sign

information and reduce noise.

It works like this: The blade position is measured using an

LED and photo transistor. The Position Sensor clock signal

is used to effectively amplify the AC signal from the Sense

Plate amplifier by either +1 or -1, depending on Rotor blade

position. This has the effect of synchronously rectifying the

AC signal, preserving sign. This rectified signal is then low

pass filtered to remove ripple. Alternatively, this circuit

function can be thought of as the mixing of two identical

frequencies, resulting in output with frequency content at

DC, and twice the input frequency. The low pass filter then

passes only the DC component. This line of thought will also show

how noise at frequencies other that the position clock frequency

are rejected.

Field Mill Fabrication Notes:

Chopper Blades

Get a 4 inch diameter duct fan with fan blades as

shown.

Remove

the fan and break off every other fan blade. Flatten the

remaining blades in a vise.

Housing

I cut a shield from brass and

mounted

it over the motor

too shield the sensor from motor 60 Hz. I don't know how

necessary this really was.

Sensor Plate Mounting Brackets

Cut 3 stripes of brass (about .5 x 2 inches), fold about

in half and drill. Drill three holes so that the

ledge is about 1.5 inches

down from the top. Attach the plastic Sensor Plate hardware

to the brackets and mount the brackets inside the housing as

shown.

Motor Shaft

Drill a hole (the same size at the motor shaft.) clean

through a piece of .5 inch diameter delrin. Drill and

tap the set screws. Cut a piece of stock the same size as the

shaft and mount as

shown

.

Note: My goal was initially

to insolate the chopper rotor, but then found grounding

was required. So you may be able to fabricate the Mill

without having to extend the shaft like this. I did have

to cut the end off the motor shaft to fit the extender

back far enough, and did end up with some wobble on the

extended shaft You could move the whole motor forward as

well if needed.

Sensor plate and Ground Plate

Lay the Chopper blades on a sheet of .015 thick brass.

Trace the outline of the chopper plate using a scribe and

cut it out using tin snipes. Drill the center and cut to

size using a nibble tool. Scribe a circle on a piece of brass

and cut it out. Flatten both pieces (use a tap hammer on a

flat metal surface) and cut out the center hole. Tap the two

pieces together and drill 5 holes around them as shown.

Assemble the sensor plate/ground plate using plastic hardware and

spacers. Transfer the position of the mounting bracket to the

Ground Plate by placing a blob of pink finger nail polish

(thanks Anne) on the

end of each screw and gently setting the Ground Plate down

on it centered. Let the polish dry and drill the three mounting

holes in the

Ground Plate

.

Position Detector

Get a photo interrupter detector as

shown

at The Shack.

Position it right at the edge of the Sense Plate (you may

need to cut a corner off the Sense Plate. Mark it's

position and remove the Rotor and Sense Plate Assembly.

Drill the Position Detector mounting holes and nibble the

center out. Also drill holes for the wires leading to the

Sense Plate Assembly. Mount the Position Detector and

reassemble the Sense Plate and Rotor. Adjust the Rotor

Height so the blades don't hit in the Position Detector.

Check it upside down also, as there is some end play in

the motor shaft.

Rotor Ground

Cut a strip of brass and fold it and mount it as

shown in the

Top View

.

As we expected, grounding the Chopper Rotor proved to be

necessary. When the Rotor is left floating, large static

outputs could be generated by depositing charge on the Rotor.

Grounding the Rotor eliminated this source of offset drift.

Final Assembly

Drill mounting holes for the circuit board and mount it.

Drill hole for off/on switch and mount the Power Supply in

the bottom as

shown in the Bottom View

. Attach the Ground Plate and Case Ground

to the Circuit Board. Attach the Position detector using coax

for the photo transistor output. Attach the Sense Plate using

coax grounded at the Circuit Board. Test.

Circuit Description and Notes

Power Supply

The circuit operates from a split supply (both +8 V and -8 V).

I used a 12 DC wall transformer, a 7808 three pin regulator for

the positive supply, and an ICL7660 voltage converter to generate

the negative supply (or a Linear Tech LT1044 will work, and it is

available in a DIP package from Digikey). You could also just

use a transformer with a center tap an build a positive and negative supply.

Transconductance Amplifier

I used the AD795 as inherited from Shawn Carlson's article,

but really any amp should work since input leakage induced

offsets are blocked by the AC input to the next stage. I also

placed two gain resisters, selectable with a header shorting bar.

The 1 Meg value should give about 6 kV/m output range, which should

be enough for cloud charge measurement. The 100 k value gives about a

60 kV/m output range, and is a better range for static charge investigation

(like measuring the cat). The feedback capacitor values provided a high pass

roll off about 1 kHz. Note: The ICL7660 switches at around 10 kHz,

so rolling off the amplifiers is recommended. The shield around the

first amplifier is also necessary to protect against noise from the position detector.

AC Amplifier Stage

I partitioned the gain into 2 stages of 30 to get an overall voltage gain of

about 1000. This could be done with a single amplifier, but input offset

specifications should be looked into to avoid a large output offset.

The AC coupling corner frequency for each is about 150 Hz, and both

amplifiers are also rolled off at around 1 kHz.

Position Detector Clock Generator

The photo transistor is setup to switch between the positive

and negative supply voltages. This is the level required to

control the 14066 quad analog switch. One of the anolog switch

stages is setup as an inverter to generate a complimentary clock.

Synchronous Demodulator

The output of the AC amplifier is connected to an inverter stage.

Two analog switches are used to alternately apply the inverted,

and non-inverted output to the input of the low pass filter.

The low pass filter is configured with a corner frequency of 7 Hz.

Calibration Amplifier

The output of the low pass filter is applied to a non-inverting

DC amplifier with an adjustable resister in the feed back for

calibration. Calibrate the instrument by placing a sheet of metal

10 cm above the Ground Plate. Put an adjustable power supply

across this plate and the housing ground. Change this applied

voltage from 0 V to 20V (200 V/m field strength) and note output

voltage change. Adjust the resistor until this produces 200 mV

of change (using the 1 Meg resister setting on the first amplifier).

The output voltage sensitivity will then be 1 V / (kV/m). Note:

There will be some level of background field while you do this, so be

sure to note the CHANGE in output while changing the applied field.

Circuit Board Fabrication Notes

Fabricate the

Circuit board as

shown.

Pay careful attention

to

grounding and power distribution. Using terminal blocks

is most helpful during trouble-shooting. It may be helpful

to reposition the Position Detector terminal block further

away from the Sense Plate input terminal block for reasons

discussed below.

Note: Since this circuit has a very sensitive input stage,

and uses synchronous demodulation , it becomes very sensitive

to noise generated by the position detector. The shield around

the first amplifier, and the coax shield on the wire going to the

sense plate are mostly necessary to prevent coupling of the Position

Detector clock signal into the amplifier. I also placed the

photo transistor end of the Photo Detector on top, furthest

from the Sense Plate. The Rotor may also provide some level

of shielding as well. Although there is still some low level

of coupling, these steps brought it under control (<50mV at ac

output). Perhaps I could try wrapping some copper tape around

the photo transistor and grounding it. You can characterize

the level of coupling by observing the AC output signal while

disconnecting the photo transistor at the terminal block.

Before adding the shielding and coax, this test showed several

volts at the AC output!

Copyright © 2001

James A. Campbell

All Rights Reserved

jc@izzy.net

Return to Home Page