Projects & Technical

Send Morse on your VHF Rig

by Peter Parker VK3YE - first appeared in Amateur Radio, June 2000

Everyone knows that the

best way to practice Morse is to use it on the air. But how do you send Morse if you don’t have a multimode HF or VHF

transceiver? Well, you could hold a

microphone up to a code practice oscillator, and hold the PTT down while

pressing the key, but it’s very clumsy, and the transmitted tone is likely to

be harsh. Clearly something better is

needed.

Enter

the MorseBox! It lets you send quality

Morse from a normal two metre or 70 centimetre FM transceiver. Just plug it in to the rig’s microphone

socket and you’re on the air. Using

just one transistor and a handful of other parts, the MorseBox can instantly be

switched between Morse and speech - a handy feature for those running Morse

practice sessions with readbacks.

MorseBox also includes semi-break-in to automatically switch between

receive and transmit when the key is pressed and a sidetone to allow monitoring

of keying.

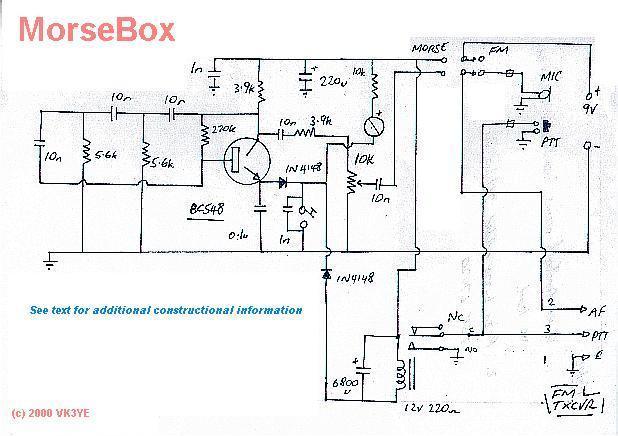

Circuit Description

MorseBox

consists of two stages. These are a

tone oscillator and a transceiver control/timing circuit (Figure One).

The

tone oscillator provides a pure tone to modulate the transmitter. It is turned on and off by keying the

emitter circuit. A twin-T circuit was

used because it is reliable and reproducible.

The output is fed to the transceiver microphone connection via a

variable resistor which is adjusted to provide a sufficient audio level for the

rig used.

The

control and timing circuit tells the transmitter when to transmit and when to

receive. Pressing the key activates

the relay and causes the rig to switch to transmit. So that the transmitter does not drop out between individual dits

and dahs, a large capacitor has been wired across the relay to provide a delay

of several seconds. This means that the

carrier is on constantly and makes for more comfortable reception. If the key hasn’t been pressed for several

seconds, the relay drops out and the transceiver switches to receive.

The

delay time depends on the value of the capacitor and the resistance of the

relay coil. Slower senders will prefer

a longer delay and faster operators will want a shorter delay. The prototype had a delay of approximately

three seconds, which should suffice for Novice speeds. Substituting a smaller value capacitor or

lower resistance relay will lessen the delay (and vice-versa). Experimentation may be required to produce

an appropriate delay from the components at hand.

The

front-panel switch allows Voice or Morse to be selected. When it is switched to voice, the MorseBox

is disabled, and the hand microphone is connected straight to the transceiver. When Morse is selected the audio from the

microphone is cut off and power is applied to the audio oscillator and relay

circuits.

A

useful feature is the sidetone or keying monitor. This allows you to monitor your own sending without needing a

separate receiver. Though an IC audio

amplifier and speaker could be used, this would increase the project’s

complexity. Instead it was decided to

use a small piezo buzzer wired between the supply rail and key as sidetone. The 10k series resistor reduces the buzzer’s

volume and extends battery life.

Construction and testing

House

the project in a metal case. This is

important to prevent the transmitted signal feeding back into the audio

oscillator and distorting the tone. The

case pictured is a 100x77x130mm box by K&W.

All

components except for the capacitor across the key socket, switch, sockets and

battery holder are mounted on a piece of unclad perforated circuit board. The parts were a tight squeeze on the

60x80mm board used in the prototype.

75x76mm boards are commercially available and would have allowed a

better layout. Component leads are

passed through the board and are soldered underneath. Vero-type stripboard could be used, but allows a less flexible

layout than the blank matrix board recommended. Because builders will use different component and circuit board

types, no component layout diagram is provided. Instead treat this project as an opportunity to build something

straight off a circuit diagram - an important amateur skill as discussed in

April’s Novice Notes.

Before

commencing construction, work out where components will be placed on the

circuit board. This is particularly

important for the larger parts, such as the relay, electrolytic capacitors and

piezo buzzer. Allow space for a hole near

each corner of the board to accommodate each spacer. Don’t forget to connect the case to the supply negative

line. This can be done in several

places - most conveniently through the key socket.

Use

a 6.5mm mono headphone socket for the key.

The only other socket on the rear panel is the connection to the

transceiver. This connection should

have sufficient pins to suit your transceiver’s microphone connections. An eight pin microphone socket and

detachable patch lead was used in the prototype, but if you’re really hard-up,

this can be replaced with a flying lead with plug to suit the transceiver.

Drill

two holes in the front panel. One is

for the Morse/Voice switch and the other for the microphone connection. No socket was used for the microphone

connection as the ex-commercial microphone used was cheap enough to be

sacrificed full-time for this project.

However one should be used if you wish to use your transceiver’s normal

microphone on the MorseBox. Don’t

forget the ferrite bead on the connection to the hand microphone - this reduces

the risk of transmitted RF getting in to the audio.

Install

the wiring around the Speech/Morse switch, relay contacts, the microphone and

the socket that carries the connections to the transceiver. Take care as this wiring quite complicated

and it’s easy to make a mistake. Trust

me, you’ll almost certainly get it wrong first time! Use the testing process described later to check for such faults

before the MorseBox is wired to the transceiver.

The

power supply used is up to the builder.

Batteries were used in the prototype to make the unit fully portable and

eliminate the need for an external supply.

A bank of six ’AA’ was used in the prototype. This is a good compromise between battery life, size and

cost. The small nine volt batteries

could be used, but have limited capacity and may give rise to oscillator chirp

near the end of their lifespan.

Schematic Diagram of MorseBox

Connecting MorseBox to your transceiver

To

connect the MorseBox to your transceiver you will need to make a cable. Because the required connections vary

between transceivers, it is not possible to provide the details here. Instead you will need to study the

microphone connections as given in your transceiver’s user manual or schematic

diagram. Identify the microphone’s

basic connections (ground, microphone audio and push-to-talk) and note any other

leads that may be present.

Transceiver

microphones are full of traps for the unwary.

Some PTT buttons do more than just key the transceiver - check for

multi-section switches that have other functions such as disconnecting the

microphone element when receiving. Also

many microphones have up-down buttons and other functions that require extra

wires. These wires should be provided

for in the cable between the transceiver and the MorseBox if these extra

features are to be available when the MorseBox is connected.

Be

prepared for the possibility that both sides of your rig’s PTT connection will

be floating above earth. This will

affect the way the Morse box is wired to the transceiver. More specifically, the NO terminal of the

relay and the earth side of the microphone’s PTT (as connected through the

front panel socket) should be disconnected from earth and wired directly to the

(formerly earthed) side of the PTT.

Connecting

the MorseBox to the transceiver is the hardest part of the project for the

newcomer. This is especially for transceivers

with complicated microphone connections.

Seek assistance from a more experienced amateur if in doubt - in extreme

cases a wrong connection may damage the transceiver and void the warranty.

Testing and Adjustment

Test

the audio oscillator by applying power, switching to Morse and pressing the

key. Set the 10k trimmer potentiometer

to about half-position. Connect a pair

of high impedance headphones, a crystal earphone or an audio signal tracer to

the lead carrying audio to the transceiver socket on the back panel. If all is well you’ll hear an audio tone

while the key is down.

If

nothing is heard, a wiring fault is likely.

Firstly check that the top end of the 3.9k resistor is +9 volts relative

to earth. If not, look for wiring errors

near the Speech/Morse switch. Wrong

connections in this area could also mean the oscillator is working but audio is

not getting to the transceiver socket.

Other reasons for failure include the transistor and the diodes being

wrongly connected.

If

you’ve wired in the buzzer, a sound from this should also be heard when the key

is pressed. If no sound, check the

buzzer’s polarity.

Pay

attention to the relay’s action.

Observe it pull in as soon as the key is pressed. The relay should remain in for about three

seconds after the key is released. In

Morse mode the relay controls the transceiver’s PTT. The three-second delay should be long enough to keep the

transmitter keyed down between Morse letters.

Connecting an audible continuity indicator (such as that found in many

multimeters) across the earth and PTT terminals on the rear panel socket should

result in a continuous tone while the key is being pressed, only dropping out

when three seconds have elapsed after the key was last touched.

Using MorseBox

The

Morse Box can be left in the transceiver’s microphone lead at all times. The ‘speech’ setting allows normal voice

operation, while the Morse setting allows Morse to be sent when the key is

pressed.

The

MorseBox has been set up for semi-break in operation with automatic switching

from transmit to receive. Operators can

switch to voice at any time with the Morse/Voice switch. This is useful if doing readbacks after text

has been sent.

Most

people would be satisfied with using the Morse Box on a two metre repeater or

simplex frequency. However, crossband

operation (possibly using ten metres, six metres or 70 centimetres) can assist

communication. This is because

receiving stations could ask for repeats or request faster sending while the

other station is sending. The effect

would be akin to the full-break-in enjoyed by proficient HF CW operators.

Parts List

(DSE catalogue numbers given for

convenience)

BC548

NPN transistor 1 Z1308

1N4148

diodes 2 Z3120

3.9k

1/4 watt resistor 2 R1088

5.6k

1/4 watt resistor 2 R1092

10k

1/4 watt resistor 1 R1098

270k

1/4 watt resistor 1 R1134

10k

trimpot 1 R1941

1nF

disc ceramic capacitor 2 R2307

10nF

greencap capacitor 5 R2055

100nF

greencap capacitor 1 R2100

220uF

electrolytic capacitor 1 R4380

6800uF

electrolytic capacitor 1 R4470 (see text)

6-9v,

220 ohm SPDT relay 1 P8008 suggested (see text)

Small

piezo buzzer 1 L7020

DPDT

toggle switch 1 P7656

Hand

microphone with PTT 1 (see text)

8-pin

microphone socket 1 P1826

8-pin

microphone plug 1 P1836

Mic

plug to suit transceiver 1 -

6.5mm

mono socket 1 P1261

6xAA

battery holder 1 S6116

Snap

to suit battery holder 1 S6100

100x77x130mm

metal case 1 H2804

75x76mm

blank matrix board 1 H5310

10mm

insulated spacers 4 H1861

Ferrite

bead 1 R5425

Conclusion

A

device to allow the transmission of Morse on VHF/UHF FM-only transceivers has

been described. It is simple to build and

provides an easy way for amateurs to practice Morse on the air. It would also be an ideal club or group

project for those wishing to increase their Morse skills together.

back to Gateway Projects

& Technical Page

This page was produced by Peter Parker VK3YE parkerp@alphalink.com.au. Material may be copied for personal or non-profit use only.