| This version reflects the comments of the core participants as reviewed and incorporated in accordance with CORD's FIPSE-supported Curriculum Morphing Project. | ||||||||||||||

MODULE 3 Changes in red were made as a group by Pete Latham – course director, Yoriko Morita, Nick Massa andTung Jeong. (1) Semiconductor lasers are diodes that emit coherent light by stimulated emission. They consist of a p-n junction inside a slab of semiconductor that is typically much less than a millimeter in any dimension. Excitation is provided by current flow through the device, and the cleaved ends of the diode provide the feedback mirrors. (2)The output characteristics of diode lasers differ from those of other laser types in two important ways. Because of their small size they have large beam divergence angles of as much as 20░ . The nature of the active medium also allows lasing over a broad wavelength range and produces an output that is far less monochromatic than other laser types. Nevertheless, semiconductor lasers have important applications in communications and range finding. Diode lasers are also being developed for medical and industrial applications. (3) This module discusses in detail the construction and operation of a gallium arsenide semiconductor laser, the most common type. In the laboratory the student will operate a gallium arsenide laser and measure its output characteristics.

Upon completion of this module, the student should be able to: 1. Draw and label a diagram of a simple gallium arsenide laser. 2. Explain the charge flow through a semiconductor in the n-region, the p-region, and the junction. 3. Draw and label the energy-level diagram of the gallium arsenide laser; use the diagram to explain the energy transfer during the lasing process. 4. Explain the design of four junction configurations used in gallium arsenide lasers and the characteristics of each. 5. Draw a diagram showing the cross section of a stripe geometry laser diode, and explain how this configuration improves laser performance. 6. Explain how the laser wavelength and threshold current vary with operating temperature. 7. Describe the spectral output of a gallium arsenide laser. 8. Describe the beam divergence of a laser diode, and explain the factors leading to this divergence. 9. Describe two processes that produce damage in laser diodes. 10. Explain two important applications of laser diodes. 11. Operate a gallium arsenide laser in the laboratory and measure its output characteristics.

Energy Transfer In Semiconductor Lasers (4) Semiconductors are materials that have electrical conductivity intermediate between the high conductivity of metals and the low conductivity of insulators. In a good electrical conductor, such as a metal, so that conduction of electricity is easy. In an insulating material (for example, common table salt), the electrons are tightly bound to their parent atoms and are not free to move through the material when a voltage is applied to it. Therefore, the electrical conductivity is low. In a semiconductor the outer electrons are usually weakly bound to their parent atoms, but a small fraction of them can migrate through the material, so that there is a small amount of electrical conductivity. (5) The most commonly known semiconductors are silicon and germanium, which have been used for electronic applications such as rectifiers and transistors. However, silicon and germanium have not yet been used in lasers. The most common semiconductor material that has been used in lasers is gallium arsenide, which is a compound of chemical element 31, gallium, and chemical element 33, arsenic. Its chemical designation is GaAs. Other semiconductor materials that have been employed as lasers are discussed later in this module, but the most common semiconductor laser, and the only one that is widely available commercially, is gallium arsenide.

Current Flow Through A Semiconductor (6) Semiconductors such as silicon are characterized by having four electrons in their outer atomic shell. In the semiconductor crystal each atom forms electron pair bonds with four other atoms. The configuration of atoms in a semiconductor crystal is called a crystaline lattice. Each of these contributes an additional electron, resulting in a total of eight electrons which completely fills the outer atomic shell. By sharing each of its four outer electrons with four neighboring atoms, each atom "fills" its outer shell. This leaves no free electrons for conduction in a pure semiconductor. Some conduction occurs because the outer electrons are not tightly bound to the atoms and may be freed by thermal or electrical energy. Thus pure semiconductors have a high electrical resistance at low temperature and lower resistance at higher temperature. (7) The electrical conductivity of a semiconductor can be increased by adding doping elements, or small percentages of impurity elements, to the semiconductor. The presence of the small traces of impurity elements can yield extra charge carriers which are free to move through the material. (8) In the compound gallium arsenide, each gallium atom has three electrons in its outermost shell of electrons and each arsenic atom has five. This gives an average of four electrons per atom in the compound. When a trace of an impurity element with two outer electrons, such as zinc, is added to the crystal, the result is the shortage of one electron from one of the pairs. This shortage sets up an imbalance in which there is a place in the crystal for an electron but there is no electron available. This is commonly called a "hole." This forms the so-called p-type semiconductor in which the conduction of electricity is by motion of the hole from one atom to another. Here p stands for positive, because the hole, or lack of an electron, looks like an extra positive charge. (9) When a trace of an impurity element with six outer electrons, such as selenium, is added to a crystal of GaAs, it provides on additional electron which is not needed for the bonding. This electron can be free to move through the crystal. Thus, it provides a mechanism for electrical conductivity. This type is called an n-type semiconductor, where n stands for negative because the carrier of electricity is the negatively charged electron. (10) When p-type and n-type regions are grown side by side in a semiconductor material the result is a p-n junction. On one side of the junction conduction is by electrons, and on the other side it is by positive holes. Such a device is called a diode, and it allows current flow in only one direction. (11) When a forward voltage is applied to the junction, i.e., the positive side of a battery is connected to the p-side and the negative to the n-side, the density of the carriers, both p-type and n-type, increases around the junction. Electrons move into the junction from the n-type side, and holes move into the junction from the p-type side. The battery applies energy to the electrons and holes, so that they are freed into a higher energy state. Because a hole is essentially the lack of electron in a bond, the hole may be filled with one of the extra electrons. When a reverse voltage is applied to the junction, the charge carriers move away from the junction to create a depletion region with no charge carriers. Thus, only a very small current flows when the diode is reverse biased.

Emission of Light by Semiconductor Diodes (12) Figure 1 shows the energy-level diagram of a GaAs semiconductor diode. In semiconductor materials, electrons may have an energy within certain bands. In the figure the lower region is called the valence band and represents the energy states of bound electrons. The upper region is called the conduction band and represents the energy states of free or conduction electrons. The conduction band is drawn above the valence beam because it indicates a higher energy level. Electrons may have energies in either of these bands, but not in the gap between the bands. Fig. 1

(13) Figure 1a shows the relative populations of the energy bands or both sides of a p-n junction with no voltage applied to the diode. The n-type material contains electrons which behave as the current carriers in its conduction band, whereas the p-type material has holes for carriers in its valence band. When a forward voltage is applied to the diode, the energy levels are caused to shift as illustrated in Figure 1b. Under these conditions there is a significant increase in the concentration of electrons in the conduction band near the junction on the n-side and the concentration of holes in the valence band near the junction on the p-side. The electrons and holes recombine (conduction band electrons move into empty valence band states) and energy is given off in the form of photons. As the electron recombines with a hole it moves from a higher energy state in the conduction band back to the lower energy state in the valence band. The energy of the photon resulting from this recombination is equal to that associated with the energy gap. That is the difference in energy between the conduction and valence bands as shown by Fig. 1b. This energy is often in the form of electromagnetic radiation. In light-emitting diodes (LED) this light energy is transmitted out through the sides of the junction region. For the LED, all of the light is created by spontaneous emission due to electron and hole recombination. In semiconductor lasers the junction forms the active medium, and the reflective ends of the laser material provide feedback. Because of this feedback in diode lasers, most of the light is created by stimulated emission.

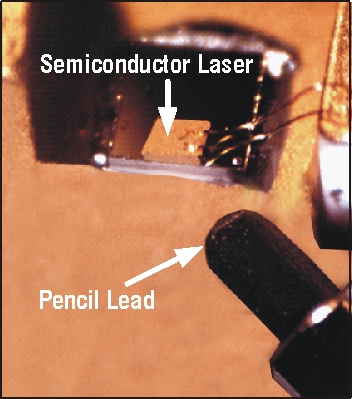

Gallium-Arsenide Laser Construction (14) GaAs lasers are prepared from ingots of gallium arsenide crystals that are mounted on a substrate glass plate with wax and cut into slices, usually about 0.5 mm thick. After the slice is formed, the junction is prepared by diffusing impurities in from the surface. Thus, if the original ingot is n-type, a p-type impurity (for example, zinc) is diffused in. The diffusion is carried out by sealing the gallium arsenide slice into an evacuated ampoule, together with a weighed amount of zinc. The ampoule is then heated in a furnace. Zinc vapor diffuses a short distance (a few microns) into the surface of the slice and forms a p-n junction. The slice then is cut or cleaved into blocks of suitable size to form the individual lasers. The blocks are small and fragile and are mounted by sandwiching them between two gold-clad metal disks. Typical dimensions of the block are of the order of one or two millimeters. The light-emitting region—that is the junction—from which the radiation originates, is a thin layer only a few microns thick. The completed laser diodes are then attached to a copper heat sink on one side and a small electrical contact on the other.

Basic Semiconductor Laser Design (15) Figure 2 is a diagram of the simplest (and earliest) type of gallium arsenide laser. The laser is a brick-shaped piece of GaAs prepared by the process outlined above. GaAs cleaves easily along certain crystal planes, leaving flat parallel surfaces. Fig. 2

(16) Usually, the mirrors for feedback and output coupling are formed by the cleaved ends of the laser diode, with no further coating. The reflectivity at the interface between gallium arsenide and air is approximately 36%. If output is desired from only one end of the device, or if mirrors of higher reflectivity are desired to reduce the threshold for laser operation, the reflectivity may be increased by coating the surfaces with metal films. Optical standing waves may exist between any two of the parallel surfaces of the diode. Two sides are purposely roughened to reduce reflection and prevent lasing "across" the diode cavity. (17) Because the diode laser is not 100% efficient, not all of the electrical energy input goes into creating photons. Some input energy into the semiconductor crystaline lattice itself. This elevates the bulk temperature of the semiconductor, but does not contribute to lasing. (18) The output power available from this laser is limited by the loop gain available within the laser cavity. The amplifier gain of the active medium is dependent on the current density through the junction. Higher currents produce greater power, but higher currents also increase heating effects that can damage the device. (19) Loss in the laser cavity has two primary contributors. The first of these is diffraction loss. The active region has a width of only about a micron. Thus, light quickly diverges out of the active region. This loss may be reduced by making the junction wider and by better confining the light to the active region. The second loss factor is absorption of the laser light by free carriers in the junction region. This loss may be reduced by reducing the number of free carriers. This reduction is accomplished by lowering the temperature of the device.

Heterojunction Laser Design (20)Heterojunction lasers are GaAs laser diodes with an advanced junction design to reduce diffraction loss in the optical cavity. This is accomplished by modification of the laser material to control the index of refraction of the cavity and the width of the junction. (21)The p-n junction of the basic GaAs laser described above is called a homojunction because only one type of semiconductor material is used in the junction with different dopants to produce the junction itself. The index of refraction of the material depends upon the impurity used and the doping level. Figure 3a shows the variation of index of refraction across such a junction. The junction region is actually lightly doped with p-type material and has the highest index of refraction. The n-type material and the more heavily doped p-type material both have lower indices of refraction. This produces a light pipe effect that helps to confine the laser light to the active junction region. In the homojunction, however, this index difference is low and much light is lost. (22)Figure 3b shows a gallium arsenide-aluminum gallium arsenide heterojunction. A fraction of the gallium in the p-type layer has been replaced by aluminum. This reduces the index of refraction of this layer and results in better confinement of the laser light to the optical cavity. By varying the amount of aluminum, changing x in Fig. 3b, the wavelength of the laser output can be varied. Fig. 3

(23)A further improvement is shown in Figure 3c. In this case, only the junction region is composed of gallium arsenide. Both the p and n regions are of aluminum gallium arsenide. The result is better confinement of the optical standing wave on both sides of the optical cavity. This confinement greatly reduces the optical loss, but also leads to two additional difficulties. The optical radiation in the cavity is so well confined that the irradiance at the diode optical surfaces may easily reach the damage threshold, increasing the likelihood of catastrophic failure. The tight confinement of the beam also reduces the effective width of the output aperture of the laser. This increases the divergence angle in the direction perpendicular to the junction. As in Fig. 3b, the wavelength can be changed by varying the aluminum concentration, x. (24)These difficulties are overcome by a further development shown in Figure 3d. This device is called a large-optical-cavity (LOC) laser and uses regions of aluminum gallium arsenide of varying composition. The active region consists of the GaAs layer at the center of the structure. High gain and lower-current operation are achieved by confining the charge carriers to a smaller region. The typical width of this region is from 0.1 to 1.0 micron. The optical cavity of the system is the width w of the diagram and is typically several microns. This reduces the diffraction loss of the system. (25)Each of the advances described has lowered the operating threshold of GaAs lasers. Table 1 lists the typical current densities necessary to achieve the lasing threshold of the various junction types. In this case, there is considerable flexibility in laser wavelength by varying the amount of aluminum in the layers, changing x and y. Table 1. Typical Threshold Current Density for

Stripe Geometry (26)In the laser shown in Figure 2, the top electrode covers the entire top surface of the p-type material. This allows current flow across the full width of the diode, which is typically several hundred microns. The current density, and thus the gain, can be greatly increased if current flow is confined to a narrow strip of the junction. This does not greatly reduce the maximum current that can be used, as the current limitation is the heating effect in the material. (27)Figure 4 shows a cross section of a large-optical-cavity heterojunction laser diode with stripe geometry for current confinement. The diode junction is constructed in the usual fashion. A layer of silicon dioxide insulating material is then deposited on the top of the diode, except for a strip about 13 microns wide down the center of the diode. The metal electrode is then applied. The result is a laser diode in which the current is confined to a single line along the length of the laser. Fig. 4

Output Characteristics of GaAs Lasers (28)Gallium arsenide lasers are different from most other types of lasers in their

properties. They possess few of the properties that are usually associated with lasers.

The small dimension of the junction is which the light is produced leads to a beam divergence (29)The spectral width of the radiation from the gallium arsenide laser is typically around two or three nanometers, much larger than the spectral width of most other lasers. Therefore, a gallium arsenide laser can be regarded as a small bright area source of radiation. Although gallium arsenide lasers do not possess the properties of directionality and monochromaticity to the same degree as other lasers, they do have many important properties that make them attractive for some practical applications. They can be modulated easily at high frequencies by modulating the current through the junction. They are efficient, small, and rugged, and are much less expensive than other types of lasers. Their small size makes semiconductor diode lasers readily packageable for multiple applications.

Temperature Dependence of Laser Output (30)The current threshold for lasing in GaAs is strongly temperature-dependent, as shown in Figure 5. At low temperature (up to approximately 30 ░ K) the threshold is fairly constant. Above 100 ░ K, the threshold current density for laser operation increases rapidly with increasing temperature. At the cryogenic temperature of 77 ░ K, the threshold current in a gallium arsenide laser is about one tenth that of the room temperature value. This means that cooling to cryogenic temperatures changes the operating and performance characteristics of the laser. Fig. 5

(31)Gallium arsenide lasers emit radiation in the near infrared portion of the spectrum. The exact wavelength depends on the temperature at which the laser is operated. This is shown in Figure 6 which gives the wavelength of a gallium arsenide laser as a function of temperature. At temperatures above room temperature, the threshold for laser operation rises and it becomes difficult to operate the laser. However, gallium arsenide lasers have been operated over the range of temperatures from liquid helium temperature to room temperature. Fig. 6

(32)The wavelength at which the laser emits is strongly influenced by the temperature of operation. However, other factors can also have an influence. These factors include the exact nature and concentration of the doping elements used in the gallium arsenide, the driving current, and the presence of a magnetic field. Thus, for a particular laser, the wavelength of emission can vary from that indicated in Figure 6. Table 2 lists typical properties of GaAs lasers. Table 2. Typical Properties of GaAs Lasers.

Temporal Characteristics

Spectral Characteristics (34)Operation of a gallium arsenide laser is characterized by a threshold current. Figure 7 shows the peak pulsed power of a typical GaAs laser as a function of the peak current input. The threshold current for this diode is about 10 amperes. When the current through the device is relatively low, a broad spectrum of spontaneous emission with a bandwidth of around 100 nanometers is observed. When the current through the junction is increased stimulated emission will begin when the optical gain exceeds the losses. The threshold current density will depend on the temperature, on the absorption losses in the material, on the reflectivity of the diode surface, and on the doping of the material. Fig. 7

(35)When the threshold current density is exceeded, the emission spectrum narrows dramatically and the intensity of the emission increases considerably. Figure 8 shows the emission spectrum of a laser diode below and also above threshold. At higher currents the linewidth of the laser output decreases. (36)The width of the spectral band represented by the spontaneous emission is much greater than that of the stimulated emission. However, stimulated emission produced by the laser is still much broader than that of conventional gas and crystalline lasers. It is of the order of two or three nanometers, as compared to a typical spectral width around 10–3 nanometers for a HeNe laser. (37)The emission spectrum is relatively complex and typically contains a number of longitudinal modes of the optical cavity. The spacing between longitudinal modes is relatively large, because of the short length of the optical cavity. However, the relatively large spectral width of the GaAs laser allows several modes to be present. Fig. 8

Spatial Characteristics (38)One of the most important characteristics of gas lasers is the very small divergence of the emitted radiation. This characteristic is not shared by semiconductor lasers. The main reason is that light is emitted through the aperture defined by the small junction. Diffraction through the narrow dimensions of the junction causes the beam to spread into a broader angle than is observed with other types of lasers. Figure 9 illustrates the beam divergence of a typical GaAs laser. The emission from a gallium arsenide laser tends to be an elliptical beam with a full angle divergence around 20░ in the direction perpendicular to the junction and around 5░ in the direction parallel to the junction. These angles may vary considerably with individual lasers. Fig. 9

Laser Lifetime (39)Two different types of failure mechanisms have been identified in gallium arsenide lasers. One is a catastrophic decrease in the power output. This catastrophic damage may occur within a single pulse of the laser, and it is associated with damage of the end surfaces of the laser. The damage is produced by the light output of the laser itself. Tiny cracks or grooves in the junction are produced. To avoid this type of damage, peak power output of the laser must be limited. For pulse durations around 100 nanoseconds, the power output should be limited to no more than approximately 400 watts per cm length of the junction. For longer pulse durations, peak power must be reduced further. (40)There is also a gradual increase in power, which is manifested by increasing threshold current. This damage is produced by the current flowing through the junction. This is a complex phenomenon that is complicated by random variations in the laser life. Some lasers have been repetitively pulsed at 8000 pulses/second for periods of hundreds of hours. Other similar laser have shown marked decreases in their output after only 100 hours of operation. To extend the life of the laser diode, current density through the junction should be limited. Operation at cryogenic temperature, where the current density is reduced because of reduced threshold current, gives safe operation at high duty cycles. Current density should be limited to a value less than approximately 6500 amperes/cm2 at the junction.

Applications of GaAs Lasers (41)Potential applications of gallium arsenide lasers are defined by the properties of this type of laser. Gallium arsenide lasers are different from other types of lasers. In particular, they do not share the narrow beam divergence angle and narrow spectral line width that commonly are associated with lasers. Because of this fact, applications of gallium arsenide lasers are somewhat limited. They cannot be used well for alignment because of the large beam divergence. They cannot be used well for interferometric applications because of the large spectral width. (42)However, other properties of small-size, light weight, low power consumption, and high efficiency are important characteristics. (See Figure 10) They mean that gallium arsenide lasers can be considered for applications in the field, away from light sources of electrical power. Two such applications that suggest themselves are range finding and communications. Both of these applications take advantage of the fact that the gallium arsenide laser can be modulated at high frequency through the power supply.(43)In ranging, a short optical pulse is send out and a return from a reflecting surface is received back at the same position as the laser. The round-trip transit time is measured. A clock is started when the original laser pulse goes out. When the return pulse is received from a remote reflector, the clock is stopped. Because the velocity of light is known, the elapsed transit time yields a measurement of distance. For surveying purposes, a cooperative target such as a reflecting mirror can be used. The ranging application using lasers takes advantage of the high radiance of the laser are compared to other light sources. High radiance is necessary to give a large signal return at the position of the detector. This yields a high signal-to-noise ratio, so as to deliver high precision in the pulse measurement. Commercial ranging systems that use gallium arsenide lasers are becoming available. (44)Simple portable communication systems that use gallium arsenide lasers have been developed. This application takes special advantage of the relative ease of modulation of the gallium arsenide lasers through varying the current. Pulse repetition rates of the order of megahertz are easy to obtain with pulsed power supplies.

Other Types of Semiconductor Lasers (45)In addition to gallium arsenide lasers, a variety of other semiconductor lasers

have been developed. Most of these lasers are in the laboratory development and have not

reached commercial status. Table 3 gives some other semiconductor laser materials, and

their wavelengths of operation. Those indicated by the letter I are pumped by injection,

which is the direct-current flow described in this module for GaAs lasers. Table 3. Semiconductor Laser Materials.

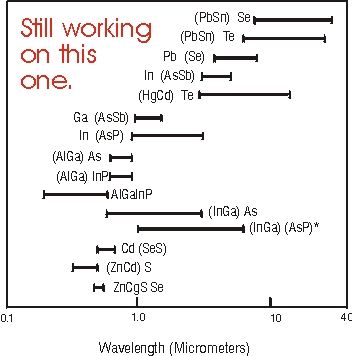

(46)Mixtures of some of these materials have been formed to allow operation at any wavelength within a range as shown in Figure 10. For example, a mixture of indium arsenide and gallium arsenide can be made. The laser is denoted by (InGa) As and may be constructed to operate anywhere in the wavelength range from 0.84 m to 3.1 m . This is accomplished by varying the ratio of gallium and indium in the laser material. Thus, the wavelength of operation may be varied over a wide range by varying the composition. Of course, once the ration is chosen and a particular wavelength is selected, that diode laser will operate only at that selected wavelength. To operate at a different wavelength, a different laser diode must be prepared with a different material ratio. In this fashion, lasers have been prepared to cover the entire red and infrared portion of the spectrum from 0.64 to 28 microns.

Fig. 10

Summary (47)The active medium of a semiconductor laser is the junction region between a p-type material and an n-type material. Laser light is a result of stimulated emission produced by electrons giving up their energy through combination with holes in the junction region. Excitation most often is provided by current flow (injection) through the junction, although electron beams can be used in some special cases. The feedback mechanism (cavity) usually consists of the cleaved ends of the diode. (48)Diode lasers typically emit pulses with durations of about 100 nsec when operated at room temperature, although CW laser diodes can be constructed. The duty cycle is typically low, usually less than one percent, and the beam divergence angle is high in the direction perpendicular to the junction producing an elliptical output beam. (49)Semiconductor lasers are most often used in range finders and in laser communications.

1. Draw and label the energy-level diagram of a GaAs laser diode. 2. Describe the mechanisms of current flow in a laser diode through each of the following regions:

3. Describe the process by which light-emitting diodes produce light. 4. Draw and label a diagram of a GaAs laser diode. Describe the four elements of this laser. 5. Explain improvements in laser performance produced by each of the following design features:

6. Explain the two primary loss mechanisms in semiconductor lasers. 7. A GaAs (n = 3.5) laser diode has a length of 0.75 mm and operates over the wavelength range of 882 nm to 884 nm. Determine the number of longitudinal modes in the laser output. 8. Explain the two primary failure mechanisms in semiconductor lasers.

Gallium arsenide laser with pulser and power supply 2 Fast PIN photodiodes for pulse shape direction Oscilloscope Optical power meter IR phosphor card X-Y translation stage Metal plate with 1-mm hole Laser safety goggles

In this laboratory the student will operate a GaAs laser diode and measure its output characteristics. Students should read the laser operation manual before beginning the lab. Observe all safety precautions during the lab. Do not operate the laser without appropriate eyeware. 1. Place the detector of the power meter to intercept the output beam of the laser diode. Distance between the two should be short to ensure that all laser light strikes the detector surface. 2. Turn on the laser, and adjust laser current through its operational range while observing the power meter. 3. Remove the power meter, and place the IR phosphor card in the laser beam. Move the card around the laser output aperture and observe the beam shape as it leaves the laser. 4. Turn off the laser. 5. Place the photodiode to intercept the laser beam. If there is a possibility of exceeding input power limits of the diode, increase the distance from the laser to the photodiode. 6. Connect the output of the photodiode to the vertical input of the oscilloscope. Most laser diode power supplies provide a "clock out" terminal that may be used to trigger the oscilloscope. 7. Operate the laser and observe the output pulses on the oscilloscope. Vary the current, and observe the effect on the pulse shape and duration. 8. Turn off the laser and remove the photodiode. 9. Mount the detector of the power meter on the X-Y translation stage. Attach the one-millimeter aperture to the detector so that light passing through it will strike the detector surface. Place this assembly in the beam path of the laser and scan the beam in the vertical and horizontal directions while the laser is in operation. This will produce an irradiance profile of the beam. 10. Use procedures described above to collect necessary data for the following descriptions of the laser output:

11. Upon completion of the laboratory, return all equipment to its original condition and secure the lab.

LABORATORY REPORT The laboratory report for this experiment is a description of the output characteristics of the GaAs laser diode and the methods used to determine those characteristics. It should include the following elements:

Gallium Arsenide Lasers and Emitters, RCA Tech. Publ. OPT-100, RCA Electronic Components, Harrison, NJ. O’Shea, Donald C.; Callen, Russell W.; Rhodes, William T. Introduction to Lasers and Applications. Reading, MA: Addison-Wesley Publishing Co., 1977. Ready, John F. Industrial Applications of Lasers. New York: Academic Press, 1978. Solid-State Infrared Emitting Diodes, Injection Lasers and Silicon Photodetectors, RCA Tech. Publ. OPT-100B, RCA Electronic Components, Harrison, NJ. Editor's Note: There are now a number of semiconductor diode laser suppliers that have information on their products on the World Wide Web.-------------------------------------------------------------

|

||||||||||||||