Four Point Probe Schematic

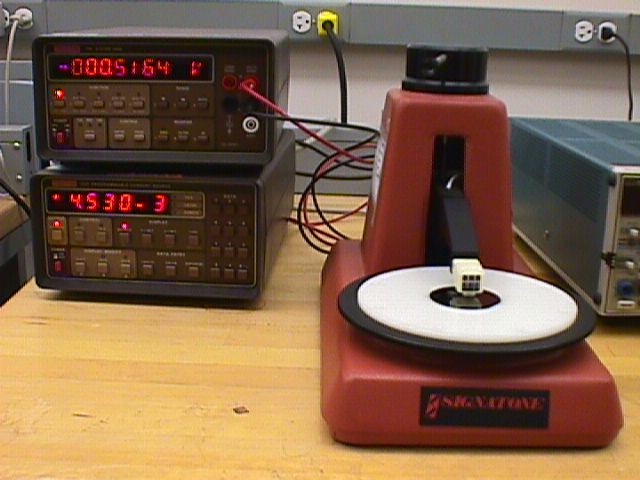

To determine the resistivity of a substrate or a thin film by using the four point probe, current source, and digital multimeter (DMM). This SOP also determines the conductivity using the four point probe and a separate function generator and DMM.

The probe tips are a very critical part of the four point probe and great care should be taken when using the equipment. Two different materials are used for the probe tips. Tungsten Carbide is a crystalline material which is very hard and somewhat brittle. If the wafer is moved horizontally while the probe arm is down, the Tungsten Carbide tips tend to break off in little pieces. The second material, osmium, is also a hard material but does not chip. When mishandled, the entire tip can be broken. Osmium tips cost more than Tungsten Carbide and are the kind used in the four point probe system at U of L. [1]

The four point probe is preferable over a two point probe because the contact and spreading resistances associated with the two point probe can't be measured. This means that the true sheet resistance can't be accurately separated from the measured resistance. The four point probe consists of two current carrying probes (1 and 4), and two voltage measuring probes (2 and 3) (refer to schematic). Since very little contact and spreading resistance is associated with the voltage probes, one can obtain a fairly accurate calculation of the sheet resistance which is then used to calculate the resistivity. The resistivity (p) of a semi-infinite wafer with equal probe spacing (s) is given by:

p=2*pi*s*V/I

Since wafers are not semi-infinite in extent, a combination of correction factors must be multiplied by the right hand side of this equation. By following the procedure below, the need for many of these factors is eliminated. The correction factors still needed, and the final forms of the formulas for sheet resistance and resistivity are given below in the procedure section. [2]

Sheet Resistance (Rs) = p/t= (V/I)*C.F.1*C.F.2

where p is the resistivity,t is the thickness of the sample, and C.F.1 is the sheet resistance correction factor which depends on the wafer diameter (d) and the probe tip spacing (s). For the UofL setup, s is equal to 62.5 mils. If the ratio of d/s is greater than 40, the sheet resistance correction factor levels off at 4.5324. If the ratio is less than 40, use the table below [3] to determine the appropriate correction factor. In the rectangle columns, the number refers to the length to width ratio, with the length being the longer of the two sides. The rectangle 4 column refers to a ratio greater than or equal to 4. Rectangular samples should be tested with the length paralell to the probe tips and the width should be taken as d when determining the correction factor. s is the spacing between the probe tips (62.5 mils for UofL setup and C.F.2 is the resistivity correction factor. C.F.2 is given in the table below. For the case when t is much less than s (less than 4/10 of s), C.F.2 is simply equal to unity. [1] Note: the above equation and the table are only valid for junctions diffused on one side of the sample. A chemical source will diffuse both sides which means the back side must be removed to use these factors, or different factors must be used.| C.F.1(d/s) | Circle | Square | Rectangle L/W=2 | Rectangle L/W=3 | Rectangle L/W=4 |

|---|---|---|---|---|---|

| 1.0 | 0.9988 | 0.9994 | |||

| 1.25 | 1.2467 | 1.2248 | |||

| 1.5 | 1.4788 | 1.4893 | 1.4893 | ||

| 1.75 | 1.7196 | 1.7238 | 1.7238 | ||

| 2.0 | 1.9475 | 1.9475 | 1.9475 | ||

| 2.5 | 2.3532 | 2.3541 | 2.3541 | ||

| 3.0 | 2.2662 | 2.4575 | 2.7000 | 2.7005 | 2.7005 |

| 4.0 | 2.9289 | 3.1127 | 3.2246 | 3.2248 | 3.2248 |

| 5.0 | 3.3625 | 3.5098 | 3.5749 | 3.5750 | 3.5750 |

| 7.5 | 3.9273 | 4.0095 | 4.0361 | 4.0362 | 4.0362 |

| 10.0 | 4.1716 | 4.2209 | 4.2357 | 4.2357 | 4.2357 |

| 15.0 | 4.3646 | 4.3882 | 4.3947 | 4.3947 | 4.3947 |

| 20.0 | 4.4364 | 4.4516 | 4.4553 | 4.4553 | 4.4553 |

| 32.0 | 4.4791 | 4.4878 | 4.4899 | 4.4899 | 4.4899 |

| 40.0 | 4.5076 | 4.5120 | 4.5129 | 4.5129 | 4.5129 |

| infinity | 4.5324 | 4.5324 | 4.5325 | 4.5325 | 4.5324 |

| C.F.2(t/s) | F (t/s) |

|---|---|

| < 0.4 | 1.000 |

| 0.400 | 0.9995 |

| 0.500 | 0.9974 |

| 0.555 | 0.9948 |

| 0.625 | 0.9896 |

| 0.714 | 0.9798 |

| 0.833 | 0.9600 |

| 1.000 | 0.9214 |

| 1.111 | 0.8907 |

| 1.250 | 0.8490 |

| 1.429 | 0.7938 |

| 1.667 | 0.7225 |

| 2.000 | 0.6336 |

A four point robe can be used to determine conductivity type through use of the rectification method. With this method, "the sign of the conductivity is determined by the polarity of a rectified ac signal at a point contact to the semiconductor. When two probes are used, one should be rectifying and the other should be ohmic. Current flows through a rectifying contact to n-type material if the metal is positive and for p-type if it is negative. Rectifying and ohmic contacts are difficult to implement with two-point contacts. Fortunately, four-point probes can be used with appropriate connections not requiring ohmic contacts. An ac voltage is applied between probes 1 and 2, and the resulting potential is measured between probes 4 and 2. The voltage drop V42 is small when the ac voltage at probe 2 is positive because the metal-semiconductor junction is forward biased. But for negative voltage at probe 2, the junction is reverse biased; V42 is large and positive. The large positive and small negative ac V42 result in a dc component with the polarity of the semiconductor-metal junction voltage necessary to reverse bias the junction. For n-type V42 is greater than 0, and for p-type V42 is less than 0." [2]

References:

[1] B. Dickson, F.M. Smits, "Operation Manual for the SYS-301 Resistivity Probing System." [2] D.K.Schroder,Semiconductor Material and Device Characterization, Arizona State University, Tempe, Arizona. [3] S.M. Sze, VLSI Technology, AT&T Bell Laboratories, Murray Hill, New Jersey.Bibliography:

[1] Am. Soc. Test. Mater., ASTM Standard, F84, Part 43. [2] Am. Soc. Test. Mater., ASTM Standard, F723, Part 43. [3] W.E. Beadle, J.C.C. Tsai, and R.D. Plummer, Quick Reference Manual for Silicon Integrated Circuit Technology, Wiley, New York, 1985. [4] F.M. Smits, "Measurement of Sheet Resistivities with the Four Point Probe," Bell Syst. Tech. J. 37, 711 (1958). [5] F. Wenner,"A Method of Measuring Earth Resistivity,"Bulletin of the Bureau of Standards 12, 469-478, 1915. [6] L.B. Valdes, "Resistivity Measurements on Germanium for Transistors," Proc. IRE 42, 420-427, Feb. 1954. [7] H.H. Wieder, "Four Terminal Nondestructive Electrical and Galvanomagnetic Measurements," in Nondestructive Evaluation of Semiconductor Materials and Devices (J.N. Zemel, ed.), Plenum Press, New York, NY, 1979, 67-104. [8] R. Hall, "Minimizing Errors of Four-Point Probe Measurements on Circular Wafers," J. Sci. Instrum. 44, 53-54, Jan. 1967. [9] A. Uhlir Jr., "The Potentials of Infinite Systems of Sources and Numerical Solutions of Problems in Semiconductor Engineering," Bell Sys. Tech. J. 34, 105-128, Jan. 1955. [10] M.G. Buehler, "A Hall Four Point Probe on Thin Plates," Solid State Electron. 10, 801-812, Aug. 1967. created by Ziyi Dai modified by Thomas Mooney 8/18/97 modified by Thomas Mooney 10/28/97

[SOP LIST]